This tutorial provides an AISC connection design example. Shear connections between I-shaped sections are some of the most common connections in steel design. To help understand the required design checks in accordance with AISC 360, this article will use a design example to explain them. With this type of connection, we can also quickly get to the results of this example through the use of the SkyCiv Connection Design module. Make sure to check out the additional article on designing a moment connection.

The calculations presented here will be using the Allowable Stress Design (ASD) method. If you aren’t familiar with the difference between ASD and LRFD in structural design, make sure to check out our video explaining this.

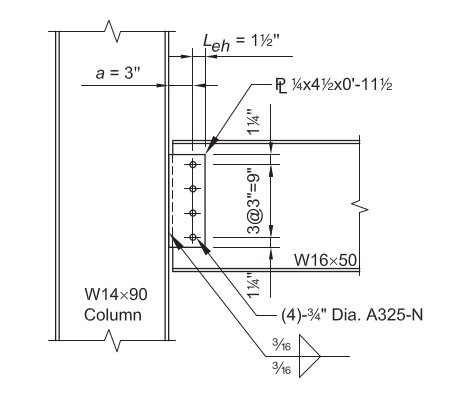

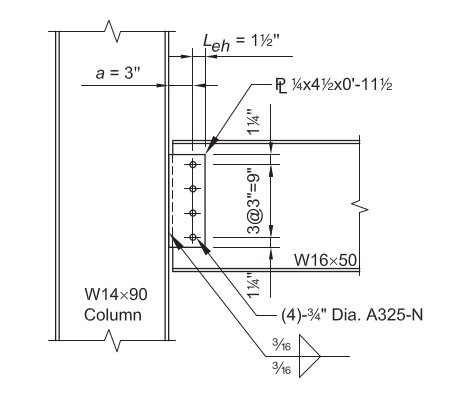

For this example, we are going to be evaluating the capacity of a single-plate connection between a W16x50 beam and a W14x90 column using the dimensions and bolts shown below. This connection needs to be able to support the beam end reactions.

Given:

Service Level Loads & Material:

Reaction from Dead Load (RD) = 8.0 kips

Reaction from Live Load (RL) = 25.0 kips

Plate Material: ASTM A36, Fy = 36 ksi, Fu = 58 ksi

Beam and Column Material: ASTM A992, Fy = 50 ksi, Fu = 65 ksi

Beam and Column Geometry:

Beam: W16x50; tw = 0.380 in, d = 16.3 in., t f = 0.630 in

Column: W14x90; tf = 0.710 in.

Shear Plate: 1/4 in thick; 4 1/2 in x 11 in dimensions

Fixtures (Bolts and Welds):

(4) – 3/4-in.-diameter ASTM A325-N bolts in standard holes

70-ksi electrode fillets

Load Calculation:

Ultimate Reaction (Ru) = 1.2(8.0 kips) + 1.6(25.0 kips) = 49.6 kips

Allowable Reaction (Ra) = 8.0 kips + 25 kips = 33.0 kips

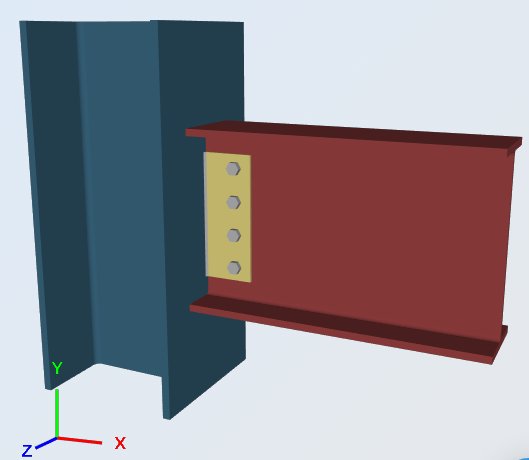

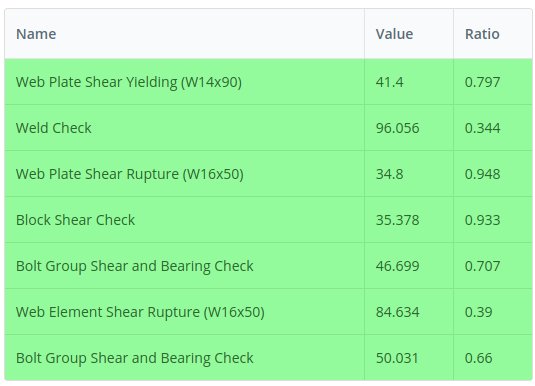

Using the SkyCiv Connection Design software, the different parts of the connection will now be checked in accordance with the Section J checks of AISC 360:

Web Plate Shear Yielding (W14x90)

Allowable Shear Capacity:Allowable Shear Capacity: Ω = 1.5

Rav = (0.6 Fy Agv / Ω) = [ 0.6 (36 ksi) (0.25 in) 11.5 in / 1.5 ] = 41.4 kips

Design capacity ratio, DCR:

required shear, Rv = 33.0 kips

overall capacity, Rav = 41.4 kips

DCR = (33.0 / 41.4) = 0.797, OK

Web Plate to W14x90 Flange, Weld Strength

Strength of Fillet Welds: Ω = 2.0

Weld Size, t = 0.1875 in

Fnw = 0.6 FEXX

Fnw = 0.6 FEXX [ 1.0 + 0.5 sin^1.5 θ ]

θ = the angle which the load makes with the weld axis

= 90, for transversely loaded welds

= 0, for longitudinally loaded welds

Strength per unit size of weld:Strength per unit size of weld:

Allowable weld stress, Faw = [ 0.6 (70) / 2.0 ] = 21 ksi

transverse length, lt = 0 in

longitudinal length, ll = 23 in

total effective length, l = lt (1.5) + ll (1.0) = 0 (1.5) + 23 (1.0) = 23 in

(Ra / t) = 483 kips / in

Effective size (throat) of fillet weld, a:

0.707 = the cosine or sine of 45deg

a = (0.707) t = 0.133 in

Ra = (Ra /t) t = 483 (0.133 in) = 64.2 kips

Design capacity ratio, DCR:

required load, R = 33.0 kips

overall capacity, Ra = 64.2 kips

DCR = (33.0 / 64.2) = 0.514, OK

Web Plate Shear Rupture (W16x50)

Allowable Shear Capacity: Ω = 2.0

Calculation of net depth:

total length of bolt hole(s) = 0.875 in (4) = 3.5 in

net depth, dnet = 11.5 in − [ 0.875 in (4) ] = 8.0 in

Rav = (0.6 Fy Anv / Ω) = [ 0.6 (58 ksi) (0.25 in) 8 in / 2.0 ] = 34.8 kips

Design capacity ratio, DCR:

required shear, Rv = 33.0 kips

overall capacity, Rav = 34.8 kips

DCR = (33.0 / 34.8) = 0.948, OK

Web Plate to W16x50 Web, Block Shear Rupture Strength

Block Shear Strength: Ω = 2.0

(Ra / Ω) = (Ubs Fu Ant / Ω) + min [ 0.6 Fy Agv , 0.6 Fu Anv ] / Ω

Tension Rupture Component: Ubs=1.0 (uniform tension)

(Ubs Fu Ant / Ω) = [ 1.0 (58 ksi) (1.0625 in) (0.25 in) / 2.0 ] = 30.8 kips/in (0.25 in) = 7.7 kips

Shear Yielding Component: 0.6 Fy Agv

(0.6 Fy Agv / Ω) = [ 0.6 (36 ksi) (10.25 in) / 2.0 ] (0.25) = 110.7 kips/in (0.25 in) = 27.7 kips

Shear Rupture Component: 0.6 Fu Anv

(0.6 Fu Anv / Ω) = [ 0.6 (58 ksi) (7.1875 in) / 2.0 ] (0.25 in) = 125.1 kips/in (0.25 in) = 31.3 kips

Total Block Shear Capacity:Total Block Shear Capacity:

(Ra / Ω)= 7.7 kips + min [ 27.7 kips , 31.3 kips ] = 35.4 kips

Design capacity ratio, DCR:

required shear, Rv = 33.0 kips

overall capacity, Rav = 35.4 kips

DCR = (33.0 / 35.4) = 0.933, OK

Web Plate to W16x50 Web, Bolt Group Shear, and Bearing Check

1. Shear Strength of Bolts: Ω = 2.0

Bolt Diameter = 0.768 in

Nominal Shear Strength, Fnv = 54 ksi

Nominal Shear Strength (per bolt), Rnv = 0.6 Fnv Ab = 0.6 (54 ksi) 0.463 in^2 = 25.0 kips

(Rnv / Ω) =12.5 kips / bolt

2. Bearing Strength of Standard Bolt Holes: Ω = 2.0

(Ignoring bolt hole deformation at service load level)

edge distance, le = 0.84 in

(clear)distance to adjacent hole, lc = 2.19 in

Since edge distance is less than the adjacent distance to the next bolt hole, edge distance will control:

(Rnb / Ω) = (1.2 lc t Fu / Ω) ≤ (2.4 d t Fu / Ω)

For the outer bolt (tearout), lc = 0.84 in:

Rnb = 1.2 lc t Fu =1.2 (0.84 in) 0.25 in (58 ksi) = 18.4 kips

(Rnb / Ω) = 9.2 kips

For the inner bolt (tearout), lc = 2.19 in:

Rnb = 1.2 lc t Fu = 1.2 (2.19 in) 0.25 in (58 ksi) = 47.6 kips

(Rnb / Ω) = 23.8 kips

For overall bearing (bolt hole elongation):

Rnb = 2.4 d t Fu = 2.4 (0.8125 in) 0.25 in (58 ksi) = 33.4 kips

(Rnb / Ω) = 16.7 kips

Bearing will control over bolt shear since 9.2 kips < 12.5 kips

3. Capacity of Bolt Group

Considering the minimum among: bolt shear capacity, bearing and tearing in inner and outer bolt holes.

a). Capacity of outer bolt (as established above):

(outer bolt) , Rab = 9.2 kips / bolt

b). Capacity of inner bolt (as established above):

(inner bolt) , Rab = 12.5 kips / bolt

c). Capacity of the bolts as a group: sum of the capacities a). and b).

Rab = 1 (9.2 kips / bolt) + 3 (12.5 kips / bolt) = 46.7 kips

Design capacity ratio, DCR:

required shear, R = 33.0 kips

overall capacity, Rab = 46.7 kips

DCR = (33.0 / 46.7) = 0.707, OK

Web Element Shear Rupture (W16x50)

Allowable Shear Capacity: Ω = 2.0

Calculation of net depth:Calculation of net depth:

total length of bolt hole(s) = 0.875 in (4) = 3.5 in

net depth, dnet =16.3 − [ 0.875 in (4) ] = 12.8 in

Rav = (0.6 Fy Anv / Ω) = [ 0.6 (58 ksi) (0.38 in) 12.8 / 2.0 ] = 84.6 kips

Design capacity ratio, DCR:

required shear, Rv = 33.0 kips

overall capacity, Rav = 84.6 kips

DCR = (33.0 / 84.6) = 0.390, OK

Web Element, Bolt Group Shear and Bearing Check

1. Shear Strength of Bolts: Ω = 2.0

Bolt Diameter = 0.768 in

Nominal Shear Strength, Fnv = 54 ksi

Nominal Shear Strength (per bolt), Rnv = 0.6 Fnv Ab = 0.6 (54 ksi) 0.463 in^2 = 25.0 kips

(Rnv / Ω) =12.5 kips

2. Bearing Strength of Standard Bolt Holes: Ω = 2.0

(Ignoring bolt hole deformation at service load level)

edge distance, le = 0.84 in

(clear) distance to adjacent hole, lc = 2.19 in

Since edge distance is less than the adjacent distance to the next bolt hole, edge distance will control.

(Rnb / Ω) = (1.2 lc t Fu / Ω) ≤ (2.4 d t Fu / Ω)

For the outer bolt (tearout), lc = 0.84 in:

Rnb = 1.2 lc t Fu = 1.2(0.84 in) 0.38 in (58 ksi) = 27.9 kips

(Rnb / Ω) = 13.9 kips

For the inner bolt (tearout), lc = 2.19 in:

Rnb = 1.2 lc t Fu = 1.2 (2.19 in) 0.38 in (58 ksi) = 72.3 kips

(Rnb / Ω) = 36.2 kips

For overall bearing (bolt hole elongation):

Rnb = 2.4 d t Fu = 2.4 (0.8125 in) 0.38 in (58 kksi) = 50.8 kips

(Rnb / Ω) = 25.4 kips

Bolt shear will control over bearing since 12.5 kips < 13.9 kips

3. Capacity of Bolt Group

Considering the minimum among: bolt shear capacity, bearing and tearing in inner and outer bolt holes.

a). Capacity of outer bolt (as established above):

(outer bolt), Rab = 12.5 kips / bolt

b). Capacity of inner bolt (as established above):

(inner bolt), Rab = 12.5 kips / bolt

c). Capacity of the bolts as a group: sum of the capacities a). and b)

Rab = 12.5 kips + 3(12.5 kips) = 50.0 kips

Design capacity ratio, DCR:

required shear, R = 33.0 kips

overall capacity, Rab = 50.0 kips

DCR = (33.0 / 50.0) = 0.660, OK

Alternatively, if you are already an experienced engineer and are familiar with the design process for a simple shear connection, the process can be substantially shortened, thanks to the design tables offered in the AISC 360 Design Manual:

Bolt Shear, Weld Shear, and Bolt Bearing, Shear Yielding, Shear Rupture, and Block Shear Rupture of the Plate

Try four rows of bolts, 1/4-in. plate thickness, and 3/16-in. fillet weld size.

From AISC Manual Table 10-10a:

Rn = 52.2 kips > 49.6 kips, OK

Rn = 34.8 kips > 33.0 kips = Ra, OK

Bolt Bearing for Beam Web

Block shear rupture, shear yielding and shear rupture will not control for an un-coped section.

From AISC Manual Table 10-1, for an un-coped section, the beam web available strength is:

Rn = 351 kips/in. (0.380 in.) = 133 kips > 49.6 kips = Ru, OK

Rn = 234 kips/in. (0.380 in.) = 88.9 kips > 33.0 kips = Ra, OK

The AISC connection design example shown above is done under ASD (the pdf version is available here: ASD Connection Design Report.pdf ). Similarly, the LRFD version example can be found in this link: LRFD Connection Design.pdf.